Digital multimeter (DMM) - A DMM measures multiple electrical quantities, such as voltage (volts), resistance (ohms) or current (amps).Having a basic toolkit with the following tools is a good place to start. Many testing tools are equipped with multifunction capabilities, incorporating more than one device into each tool. Modern motor testing tools make taking readings and analyzing a motor's current condition fairly simple once you understand how each tool works.

While the ins and outs of motor testing can be intimidating and a bit complex, knowing the basics along with using modern motor testing tools and equipment can greatly simplify the task of testing motors. Motor testing can also detect faulty electrical connections in a circuit that may not be picked up with regular infrared testing, reducing the risk of a fire. This gives personnel a de-energized working condition in which to make repairs. Motor testing reduces the urgency and frequency of breakdowns, allowing maintenance teams to shift the majority of their work to scheduled downtimes. This could negatively impact the motor's overall power quality, accelerate asset wear, and present itself as costly increases in energy consumption and peak use. Motor current analysis (MCA) testing can help identify conditions within a motor that lead to increased power consumption. What type of maintenance a motor requires or whether it needs to be replaced is a critical and potentially expensive decision. Motor testing gives you a clear picture of the real-time condition of the motors within your assets, limiting potential collateral damage due to failures and reducing maintenance costs. This clears the path for more economically planned maintenance tasks to correct discovered issues. Identifying defective motors before they reach a point of failure ensures your system(s) remain up and running. Motor testing lends itself to multiple benefits, including: Making motor testing a part of a maintenance program is important because once a motor endures damage, it is often irreversible (referred to as core damage) this leads to the motor not running with the same efficiency as it once did, if at all. Motor testing often alludes to issues before visual inspection makes them apparent. Motor testing with a preventive maintenance program can test motors while they're operating in their normal environment under normal loads to confirm they're running at acceptable or optimum limits. Motor testing is often used in a preventive maintenance or reliability-centered maintenance program.

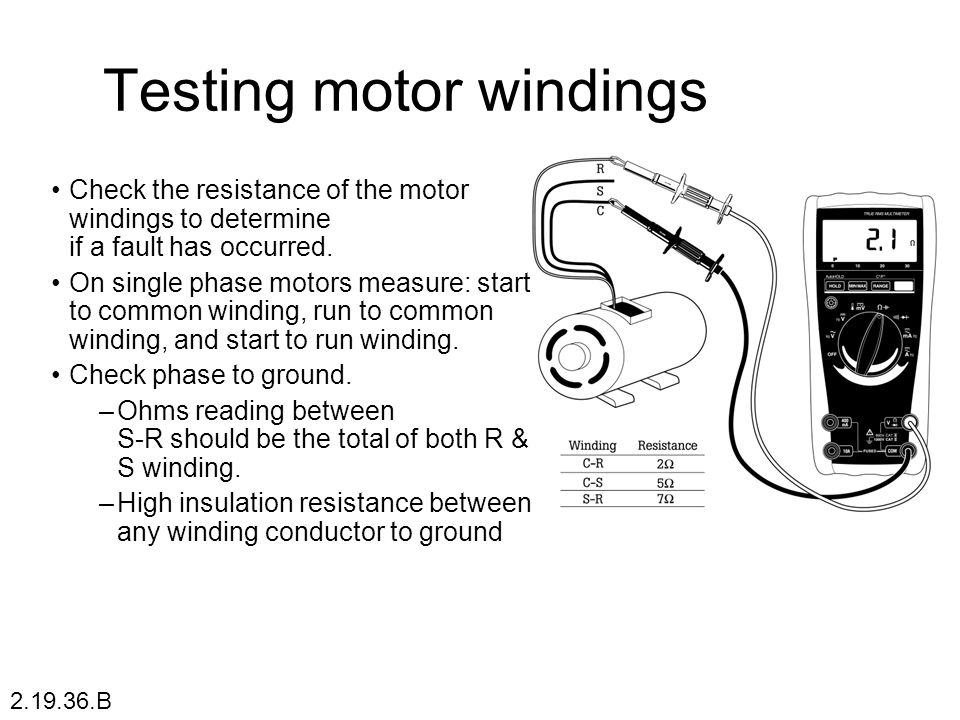

These standards are constantly reviewed and improved when deemed necessary by the board. Motor testing is regulated by the Institute of Electrical and Electronics Engineers (IEEE) through standards such as IEEE 43 – Insulation Resistance and Polarization Index, IEEE 56 – Maintenance AC Hipot Test, IEEE 95 – DC Hipot Test, and IEEE 400-2001 – The Guide for Field Testing and Evaluation of the Insulation of Shielded Power Cable Systems. While each motor test applies to most alternating current (AC) or direct current (DC) motors, each testing method depends on the construction and application of the motor in question. Mechanical motor testing includes things like looking into the cracks of a motor's rotor and lamination sheet makeup. Specific to electric motors, motor testing evaluates static parameters like insulation, wire damage and electrical current leakage, as well as more dynamic parameters such as distortion, temperature fluctuations and balance. The main objective of motor testing is to reveal hidden problems and prevent unnecessary failure. Motor testing assesses the integrity of a motor through the use of computer-supported equipment or tools that monitor trends within the motor.

0 kommentar(er)

0 kommentar(er)